2011 U.S. Department of Energy SOLAR DECATHLON

SCI-Arc + CalTech

CHIP (Compact Hyper-Insulated Prototype) is designed to challenge every architectural and engineering preconception regarding the net-zero-energy home. This project is the result of a 2-year research, design, and construction collaboration between Southern California Institute of Architecture and California Institute of Technology. Our team was selected as one of the twenty international entrants by the U. S. Department of Energy to participate in the 2011 Solar Decathlon. Each team is responsible for the safe transport and assemblage of their homes on the National Mall in Washington D.C. in a solar village where it stands on display to the public for two weeks.

collaborative work

SCI-Arc & Cal-Tech

The concepts and drawings were produced as a group effort for the SCI-Arc/Caltech 2011 Solar Decathlon competition entry. For more information, please visit www.CHIP2011.com

CHIP - Walkthrough

The award-winning Compact Hyper-Insulated Prototype (CHIP) solar home, created by students from Caltech and the Southern California Institute of Architecture, was featured at the 2011 Solar Decathlon in Washington, D.C. What makes CHIP cool and innovative? Students from both schools take you on a brief tour of this cutting-edge addition to the world of energy-conscious architecture. This video was also exhibited at the 2011 Solar Power International trade show in Dallas, Texas. Produced and Directed by Darius Siwek in collaboration with DASI.

SCI-Arc/Cal-Tech team members

Like the Olympic decathlon, the U.S. Department of Energy Solar Decathlon consists of 10 contests. These contests are designed to gauge how well the houses perform and how livable and affordable they are.

10 Solar Decathlon 2011 contests:

Architecture contest (juried), Market Appeal contest (juried), Engineering contest (juried), Communications contest (juried), Affordability contest (juried), Comfort Zone contest (measured), Hot Water contest (measured), Appliances contest (measured), Home Entertainment contest (measured and juried), Energy Balance contest (measured)

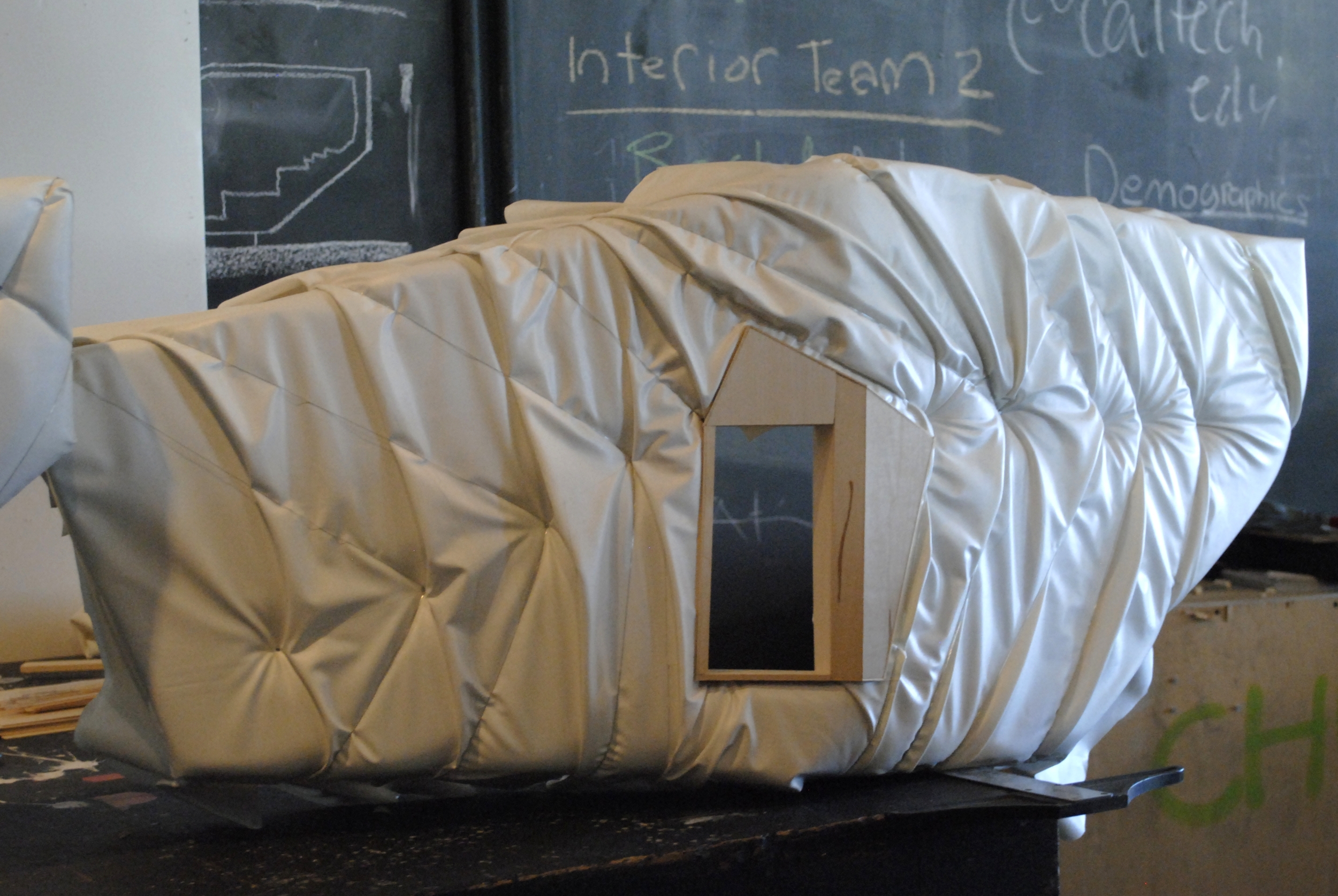

SHAPE

The primitive shape was derived from four modules of maximum standard trucking dimensions arranged to exploit the limitations of the solar envelope guidelines of the competition. Modification of this block was conducted to fulfill certain performative criteria for both the interior and the exterior of the house. The top is cut down to maximize solar gain. The bottom is cut, which creates a terraced interior, dividing the spaces while still maintaining an open floor plan. The north east and south west walls are strategically kinked in an effort to make the modest interior feel larger. The resulting shape gives CHIP its small footprint while producing an interior volume well equipped to address the issues of energy production and consumption in residential dwelling.

_floor plan

INTERIOR

The interior makes way to an organization of spaces delineated by use. While the more public exterior/living space is lowest on the south end, the spaces become more private as one ascends the steps, ending with the bedroom at the north end. While each individual level commands relatively small square footage, the open nature of the interior provides a much larger perceived space. The walls serve the central space, providing support for the program accommodated by each level change. The east wall is composed of a system of cabinets which can be rearranged or re-sized to cater to the specific needs of the home owner.

SKIN and INSULATION

Like the interior, our goal is to do more with less: maximize energy production while minimizing consumption. The main way we minimize consumption is through our insulation and exterior skin strategy. Typically, insulation is filled in between the framing studs. The gaps between insulation batting and framing are problem areas allowing precious energy to escape. Based on data collected from case studies of the passive house strategy, we decided to divorce our insulation from the limitations of standard construction - placing it, instead, to the exterior of the plywood sheeting. This allows us to increase our insulation and limit our consumption. After the insulation is attached, we wrap our entire exterior with a single fabric membrane. This envelope acts as a barrier from weather conditions while giving the house its unique soft puffy identity.

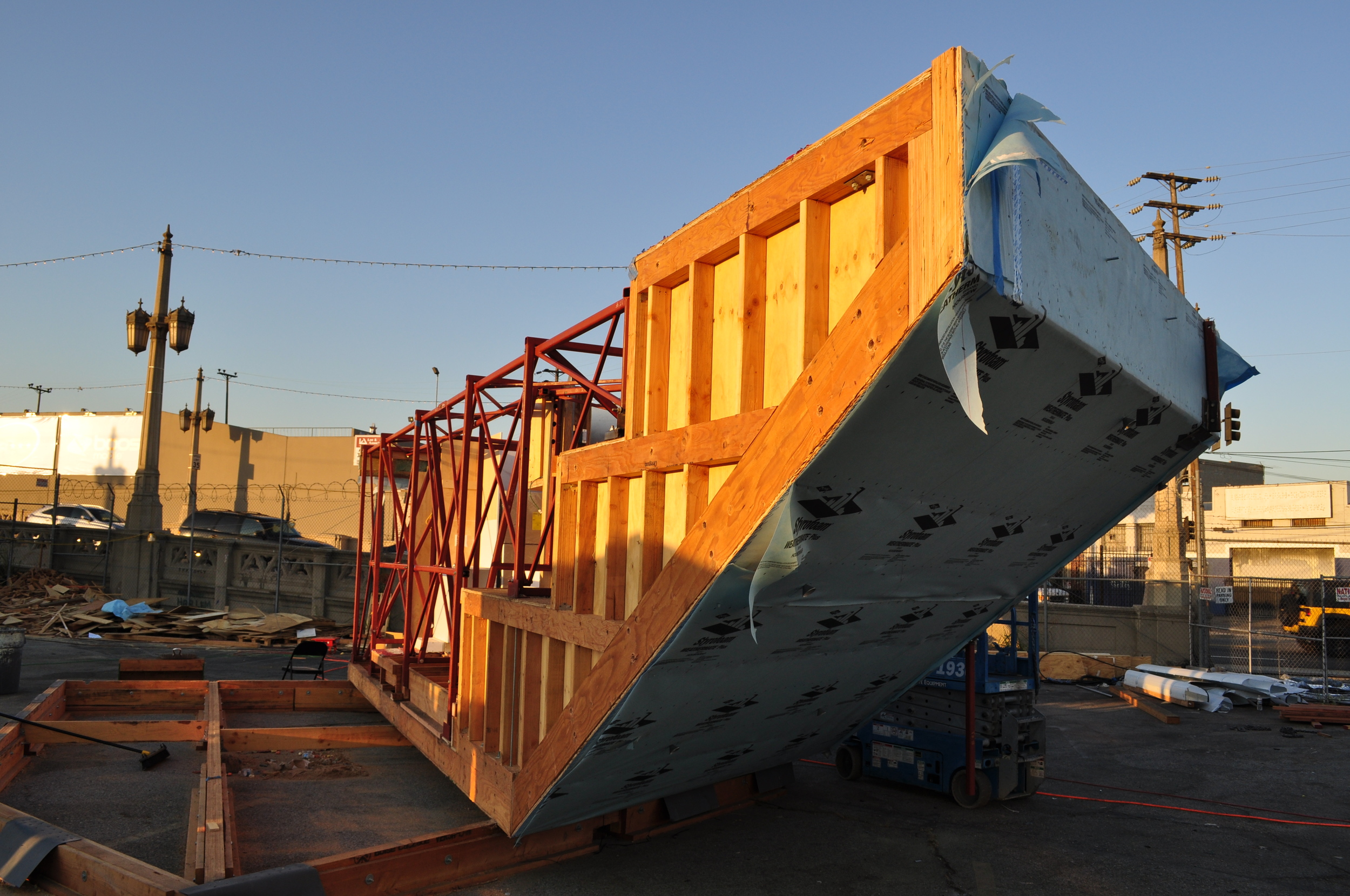

CHIP FABRICATION & INSTALL

The build. A glimpse of the student perspective.

Students were organized into task-based teams at the outset of the semester; this organization was flexible, however, and students often found themselves either working on several teams at once, or changing teams over the semester as the tasks are accomplished or the understanding of the building and its construction requirements evolved.

Each of the teams was responsible for producing the drawings used to construct their designs. Teams then proceeded to construction of their work once the instructors and the studio had approved the drawings. This process was repeated many times over the semester to produce a fully viable version of the building element for which they are responsible.

My participation included:

Design and construction documentation, project execution and delivery, project timeline coordination with project managers and subcontractors, material acquisition, job-site organization and management, construction means and methods, as well as job-site safety and procedures.

CHIP - Time Lapse

FABRICATION

MODULARITY

_module split

A difficult issue presented by the nature of the competition was solving the problems of logistics: how does each team ship their houses to Washington D.C. in a way that is both unintrusive on the mechanics and function of the building, and efficient/safe for transportation? SCI-Arc and Caltech took an innovative approach to solving this question. The CHIP house was designed to dismantle into four modules utilizing sophisticated, student-designed bracing. This system allowed for highly calibrated maneuvering of the four modules as they were pulled apart and placed individually on the back of thirty-foot flat bed trucks. This unorthodox strategy provided our team the advantage of unprecedented ease of assembly in Washington D.C.

CHIP - House Craning Day

In as little as six hours, the house could be reassembled at its new location, each module locking the other in place.

The SCI-Arc/Caltech Team splits up their Compact Hyper-Insulated Prototype solar home into pieces and trucks it off to D.C. for the Big Show (i.e. 2011 Solar Decathlon).

_craning images